LED Technology

Your current location: Blog > LED Technology

LED Technology Comparisons SMD vs COB

Time:2014-12-03 Hits:523 Compile:SNL

Doing comparison especially when selecting the LED technology to use is very vital. This is due to the fact that there are various models available and they are not similar. Some of them have more features while others have fewer features. It all depends with the needs of the shopper and thus it is important to compare them first prior buying. Once you have decided the features you would like, it becomes easier for you to select the package type.

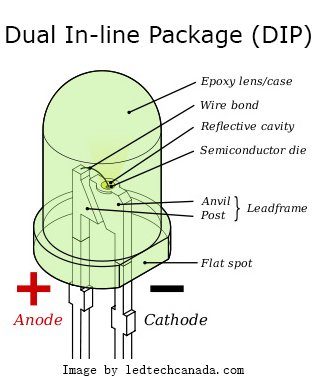

The package type basically means the way the LED’s semiconductor are similar as compared to the filament of the incandescent usually packaged inside the LED devices for various uses. The LED package may be simple just like in the DIP LEDs. However, it can also be a bit versatile to handle many needs just like with SMD package. The modern technology that we are enjoying currently was developed back in 1962 by Holonyak. His invention was the DIP LED. Since then, this industry of LEDs products has been innovating this since then. Below is just a brief review of some of the major kinds of the LED package technology which are commercially available nowadays. They include DIP, SMD, COB as well as MCOB LED technology.

DIP LED Technology

This means Dual In-Line Package technology. It has been there for more than fifty years. This what comes into mind to most people when they picture LED technology. Despite the fact that DIP LEDs have been there for quite sometimes, they are very far from being outdated. In fact, they are used extensively nowadays for large displays and signs. The widespread usage of the DIP LEDs is due to the long lifespan as well as intense brightness they normally have. The DIP LEDs are widely recognized by their bullet or pill shaped design of 5 mm wide. They have long contacts that can extend from the lower side of the LED and thus they can be soldered easily or be inserted into the bread board.

They have an epoxy and plastic casing that is used as a lens to focus the incoming light from the diode. Its outer casing has a shape that includes a flat side on one side which shows cathode side of the DIP LEDs. All these lights can be used for home or residential use. When used for this use, they are normally found in the electronics as the indicator lights due to their low cost, ease of installation as well as high brightness. The DIP diodes may be purchased in bulk by the electronic manufacturers in order to fulfil many purposes. Due to their plug and play nature, DIP LEDs can be soldered easily to any form of circuit board in order to give the electronic devices the capability to send necessary information to the uses without necessarily having a real display on the chip.

These LEDs are able to produce between three and four lumens per each LED. They basically run at between five volts to twenty-four volts. The common voltage that is mostly used is twelve volts. They each pull between a wattage of 0.05 and 0.08 watts. This helps to generate around 35 to 80 lumens per watt. However, this depends on the type of the LED being used.

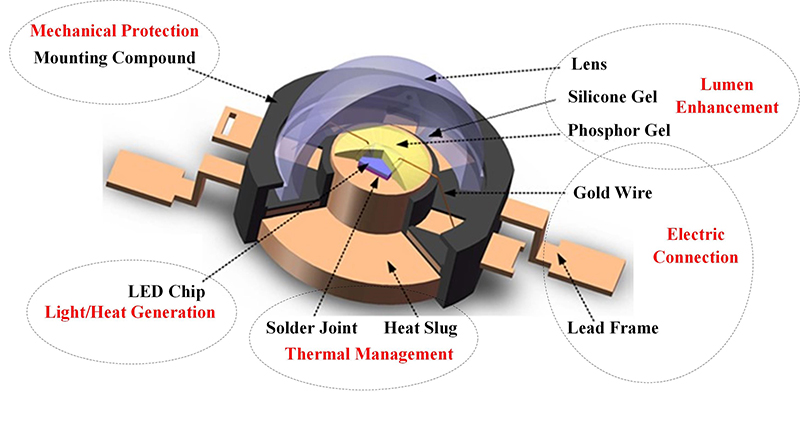

SMD LED Technology

In full this means the Surface Mounted Device Chips. Nowadays, they increased their popularity due to their availability. The SMD LEDs are used in making so many things such as strip lights, light bulbs and even in making of the missed call indicators of the cell phones. Such chips are a bit smaller in comparison with the DIP technology as they tend to have an added versatility over the DIP diodes. The SMD technology supports the chips with a bit more complicated designs like the Cree XTE SMD chips which have the RGB capabilities on the single chip. This technology does not have bullet shaped design as in the DIP LED technology.

In addition the above, its shape is near that of a flat-square computer chips. It is important to note that the SMD chips may have more than two contacts that include one cathode and one diode. The SMD chips may also have two, four or six contacts although this depends on the diodes available on the chips. With this SMD design, each circuit must have one diode. An example is that the Cree XTE SMD chips have three diodes on its chip. This translates to three circuits which give a total of six contacts. The SMD chips are usually seen in the LED high bay and the LED flood light typically produce between six and seven lumens per every diode available on the chip. These chips usually run at either 12 volts or 24 volts though 12 volts is the common voltage they run on. These chips can each pull between 0.05 watts to 0.08 watts up to between 0.15 watts to 0.24 watts for three diodes. This means that these chips are capable of producing around 70 to 120 lumens per watt. It all depends on the specific chip being used.

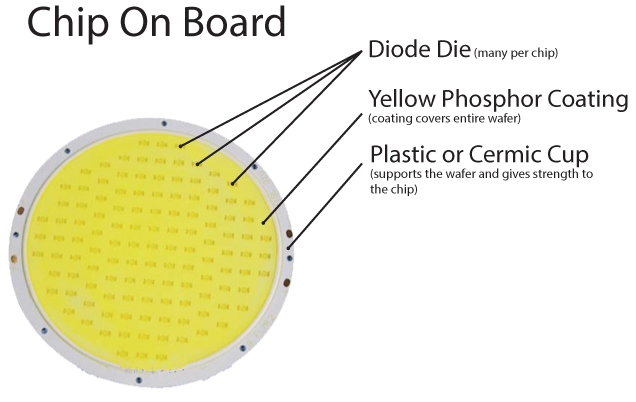

COB LED Technology

This is the most current LED development. In full it means Chip On Board Technology. Both the COB and SMD LEDs are somehow similar since both of them have chips that have many diodes on a similar clip or wafer. This is the only similarity between the two. For each COB chip, there should be multiple diodes like nine or more. Another difference between this two is the fact that whereas the SMD needs to have a circuit for all diodes put on the chip, the COB devices only require one circuit plus 2 contacts for the whole chip despite the number of the diodes it has. This is a single circuit design that is not affected by the diodes available on the chip. This results to simplicity in the rest of the COB LED chip.

The COB also results to an improved lumen per watt ratios as compared to the LED technologies like SMD as well as DIP. Conversely, the major drawback from the one circuit design of the COB chips is that the multiple channels are needed so as to adjust the individual levels of the light output. This helps in creating the color changing effects. Basically, this means that the COB technology cannot be used in creating the color changing lights or bulbs regardless of having a very powerful as well as efficient single color applications.

Prior the coming of the COB technology, the LED flood lights and spot lights were anciently considered as non-standard lamps since they needed many LED sources so as to produce high lumen output. It is worth noting that since the time the COB chips during the LED arena were invented, it became easier to give a high number of lumen counts just from one source. This is achieved by simply using the COB chip. By then, this was not possible until the coming of the COB. There has been a great revolution for all people who would like to reduce their energy bill while ensuring they have to have a standard lamp. Apart from the spotlights as well as the floodlights, the COB chips are put in all types of bulbs and they are used for various applications.

The COB technology is commonly used for the small device to flash such as camera or smartphone. The principle utilized is that the COB chips producers need to have a small 22 or 33 COB matrix so as to produce the camera flash. The point and shoot cameras also support the small COB chip which can use less energy to produce an adequate amount of light. The COB chips normally vary in the applications and hence different chips require different wattage and voltage to produce a larger variety of the lumen counts. Though, it is said that the COB chips ratio of the lumens per every watt is high about 80 lumens per watt.

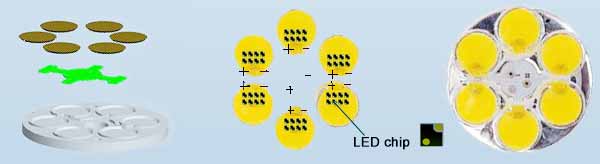

MCOB LED Technology

Since the invention of the COB chips, there was a variant that came along with the MCOB. In full this means MCOB means Multiple Chip-On-Board. The MCOB devices are similar to the COB devices especially in their application. They are either less or more COB chips accumulated together in series. However, the MCOB devices may differ from the COB devices since they are best used for the low wattage situations. To add on this, they do not fulfil the standard lamp needs for the spot lights as well as the floodlights as it was said under the COB section. The MCOB chips do not have to meet the requirements in order to be a standard lamp. In fact, they produce much more light and thus they are great for the low wattage situations such as the A19 bulbs. Nowadays, the A19 bulbs are mostly used in the MCOB LED technology. For those who will purchase the A19 in future, it is likely that they will buy an MCOB bulb.

MCOB technology is very new and thus most of the manufacturers have not started producing it. It is expected that it will catch on more that the A19 bulbs. The applications that can be fulfilled by the MCOB are many for the high lumen count. Thus, it is likely that the innovators shall use the technology in order to create the market for the new products that has never been there before. The era of the LED technology is really exciting when it continues to change and evolve. It is expected that very soon we will have yet another newer technology which will do great in the market of the LED products.

The solution of choosing SMD or COB on high power LED lights.

Below is very important information to help determine between the COB and SMD, which is better than the other. Also, to help determine which chip is better for the high power LED lights such as the LED high bay, the LED flood light as well as the LED street light.

To start with, the high power LED lights normally generate much heat when operating. The heat produced has to be transported outside in time. If the heat is not transported out of the lights in time, it may affect the performance as well as the life of the lights. Heat dissipation usually takes a vital role in these high power lights. Therefore, the LEDs may reduce the brightness quickly because of heat. Conversely to this, it may affect the lumens depreciation rate.

Regardless of the COB LED technology having the advantage of the high brightness, the high power LED lights such as the LED high bay or the LED flood lights typically generate much more heat as compared to the light bulbs or the LED spot lights. They also need to have a perfect working environment in order to dissipate the heat that will be generated from the LED power supply or the LED chips. It is worth noting that the high power COB chips are always single with fifty or a hundred watts. Therefore, they can generate much more heat as compared to the SMD devices. The COB chips do not require a larger PCB since PCB are always small.

From the above, the heat will be accumulated in a small area PCB. This means that heat cannot be emitted outside during the operation time. The temperature of the lights will thus increase quickly and the performance as well as lifespan of the lights will be decreased because of the heat. The SMD such as the CREE XTE SMD chip as well as the LEDs are normally smaller than the COB. They are always two watts or four watts for a single chip.

The manufacturer requires a lot of LEDs when producing a two hundred watts LED high bay. The PCB is larger as compared to the COB PCB. The heat from the SMD chips does not accumulate together like in the COB lights. A larger PCB usually has a faster heat transfer for the LED lights. The temperature of the SMD chips may be lower than the COB chips. Therefore, the SMD high power LED lights typically have a better efficiency of heat dissipation than that of the COB. This is the reason behind their long lifespan as well as their good performance than that of the COB high power lights. All this will help greatly in saving both more money as well as energy.